The other day, in a meeting with a system Integrator from Trivandrum (He has been a great supporter of our products and has given us tons of valuable feedback and some good business too) we were asked if it was OK to use a 60 Cell panel with 24 V battery system and a PWM charger. We had to tell him that it would be better to use a 72 Cell Panel with a 24V battery system esp with a PWM charger. (Similarly a 36 Cell panel with a 12V battery system).

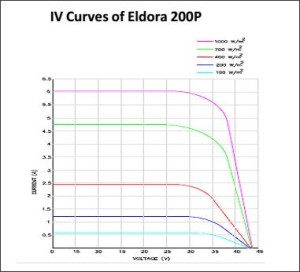

The reason is simple.The Current – Voltage curves of the 60 Cell Panel seem to indicate that the Maxi

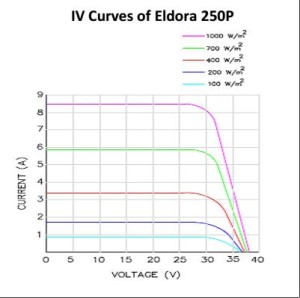

The problem with operating at the right of the knee instead of the left of the knee is obvious once we look at the curves above. On the right of the knee, we see that the curve is dropping sharply and that means that a small shift to the right on Voltage will mean a large drop in available Current – and therefore the Power ( Power: multiply I and V). Whereas if we operate to the left of the knee- the value of Current (I) does not change much and we end up getting more power in the exact same conditions. We may even be operating on the knee and getting the maximum power with the PWM charger if the knee is ‘right’ enough. Take a look at a similar IV curve for a 72 Cell panel below. Even under real life conditions, we are likely to operate at the left of the knee and that is why it is advisable to use a 72 cell panel with 24V battery systems and 36 cell panels with 12V battery systems.